Title: The Mainstream RMS to DC Converter Production Process: A Comprehensive Overview

1. Design and Specification (200 words) The production process of RMS to DC converters begins with the design and specification phase. Engineers analyze the requirements and specifications of the converter, considering factors such as input voltage range, output voltage accuracy, bandwidth, and power dissipation. They also determine the type of converter architecture, such as peak detectors, root-mean-square (RMS) converters, or logarithmic amplifiers, based on the application's needs.

2. Component Selection (200 words) Once the design is finalized, the next step involves selecting the appropriate components for the converter. This includes choosing operational amplifiers, resistors, capacitors, and diodes that meet the desired performance criteria. Component selection is crucial to ensure accurate signal processing, low noise, and high linearity.

3. Printed Circuit Board (PCB) Design (200 words) The PCB design phase involves creating a layout that accommodates all the selected components and ensures proper signal flow. Engineers use specialized software to design the PCB layout, considering factors such as component placement, signal routing, and thermal management. The layout must be optimized to minimize noise, crosstalk, and interference.

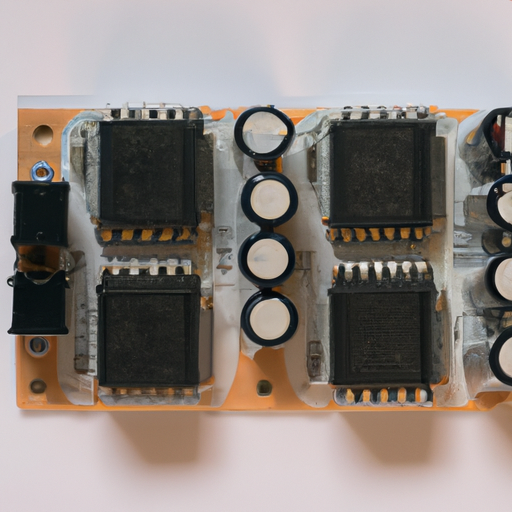

4. Prototype Development (200 words) Once the PCB design is complete, a prototype of the RMS to DC converter is developed. This involves fabricating the PCB, assembling the components, and testing the initial functionality. The prototype serves as a proof-of-concept, allowing engineers to evaluate the converter's performance and make necessary adjustments before mass production.

5. Testing and Calibration (200 words) After the prototype is developed, rigorous testing and calibration are conducted to ensure the converter meets the desired specifications. Various tests, such as input/output linearity, accuracy, stability, and temperature performance, are performed. Calibration techniques, including trimming resistors or using digital calibration algorithms, are employed to enhance the converter's accuracy.

6. Mass Production (200 words) Once the prototype passes all tests and calibration, the production process moves to mass production. This involves sourcing the required components in bulk, setting up assembly lines, and implementing quality control measures. Automated assembly techniques, such as surface mount technology (SMT), are commonly used to increase production efficiency and reduce costs.

7. Quality Control and Inspection (200 words) Throughout the mass production process, strict quality control measures are implemented to ensure consistent performance and reliability of the RMS to DC converters. Random sampling, visual inspection, and functional testing are conducted to identify any manufacturing defects or deviations from specifications. Any faulty units are repaired or discarded to maintain high-quality standards.

8. Packaging and Distribution (200 words) Once the converters pass the quality control stage, they are packaged appropriately for distribution. Packaging may include anti-static bags, trays, or tubes to protect the converters during transportation and storage. Proper labeling and documentation are also essential for traceability and customer support.

Conclusion (100 words) The mainstream production process of RMS to DC converters involves several crucial steps, from design and component selection to mass production and quality control. Each stage requires careful consideration and adherence to specifications to ensure accurate and reliable performance. By understanding this production process, engineers and manufacturers can optimize their manufacturing techniques, resulting in high-quality RMS to DC converters that meet the demands of various electronic applications.