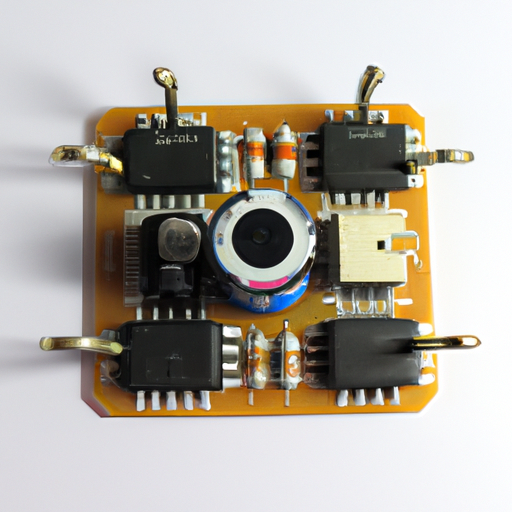

A motor driver is an essential component in many electronic systems that require precise control of motors. It is responsible for controlling the speed, direction, and torque of the motor. Motor drivers are commonly used in robotics, automation, electric vehicles, and various other applications. In this article, we will explore the different components and modules that make up a motor driver.

2. Microcontroller or Control Circuitry: The microcontroller or control circuitry is the brain of the motor driver. It receives commands from the user or a higher-level control system and generates the necessary control signals for the power stage. The microcontroller may also include additional features like speed control, current sensing, and protection mechanisms.

3. Current Sensing: Current sensing is an important feature in motor drivers as it allows monitoring and controlling the current flowing through the motor. This information is crucial for protecting the motor from overcurrent conditions and for implementing closed-loop control algorithms. Current sensing can be achieved using shunt resistors, Hall effect sensors, or current transformers.

4. Voltage Regulation: Motor drivers often include voltage regulation circuits to ensure a stable power supply for the control circuitry and other components. These circuits regulate the input voltage to a constant level, preventing voltage fluctuations from affecting the motor's performance.

5. Protection Mechanisms: Motor drivers incorporate various protection mechanisms to safeguard the motor and the driver circuitry. These mechanisms include overcurrent protection, overvoltage protection, undervoltage lockout, thermal shutdown, and short-circuit protection. These features help prevent damage to the motor and the driver in case of faults or abnormal operating conditions.

6. Communication Interfaces: Some motor drivers include communication interfaces to enable control and monitoring of the motor driver remotely. Common communication interfaces include UART, SPI, I2C, and CAN. These interfaces allow integration with other systems and enable advanced control features.

7. Motor Control Algorithms: Motor drivers may include built-in motor control algorithms to simplify the control process. These algorithms can include speed control, position control, and torque control. They help in achieving precise motor control without the need for complex control algorithms implemented externally.

8. Heat Sink: Motor drivers generate heat during operation due to power dissipation in the power stage. To prevent overheating, motor drivers often include heat sinks or other cooling mechanisms to dissipate the heat efficiently. Heat sinks help maintain the driver's temperature within safe limits and ensure reliable operation.

9. Protection Diodes: Protection diodes are often included in motor drivers to protect against voltage spikes generated during motor operation. These diodes provide a path for the reverse current generated by the motor's inductive load, preventing damage to the driver circuitry.

10. Fault Detection and Reporting: Motor drivers may include fault detection and reporting mechanisms to identify and report any abnormal conditions or faults. These mechanisms can include fault detection for overcurrent, overtemperature, and short-circuits. Fault reporting can be done through status indicators, alarms, or communication interfaces.

In conclusion, a motor driver is a complex electronic component that consists of various modules and components. These include the power stage, microcontroller or control circuitry, current sensing, voltage regulation, protection mechanisms, communication interfaces, motor control algorithms, heat sinks, protection diodes, and fault detection and reporting mechanisms. Each of these components plays a crucial role in ensuring precise control and protection of motors in various applications.