Title: The Mainstream LED Driver Production Process: A Comprehensive Overview

1. Component Selection (200 words) The first step in the LED driver production process is the careful selection of components. LED drivers consist of various electronic components, including resistors, capacitors, inductors, transistors, and integrated circuits. Manufacturers must consider factors such as component quality, compatibility, and cost-effectiveness. The selection process involves evaluating the specifications and performance characteristics of each component to ensure they meet the desired requirements for the LED driver.

2. Circuit Design (250 words) Once the components are selected, the next step is circuit design. This involves creating a schematic diagram that outlines the connections and interactions between the components. The circuit design must consider factors such as voltage regulation, current control, and protection mechanisms to ensure the LED driver operates efficiently and safely. Advanced software tools are often employed to simulate and optimize the circuit design before moving to the prototyping stage.

3. Prototyping and Testing (300 words) After the circuit design is finalized, manufacturers proceed to the prototyping stage. Prototyping involves assembling the selected components on a printed circuit board (PCB) according to the circuit design. This allows manufacturers to test the functionality and performance of the LED driver in real-world conditions. Various tests, such as voltage regulation, current stability, and thermal performance, are conducted to ensure the prototype meets the desired specifications.

4. PCB Manufacturing (200 words) Once the prototype is successfully tested, the next step is PCB manufacturing. This involves producing the PCBs in large quantities using specialized manufacturing techniques. The PCBs are fabricated by etching copper traces onto a non-conductive substrate, typically fiberglass-reinforced epoxy. Advanced machinery and automated processes are employed to ensure precise and consistent PCB production.

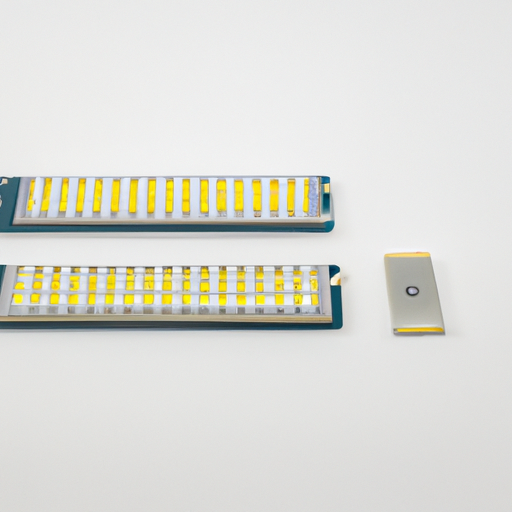

5. Component Mounting (200 words) After the PCBs are manufactured, the next step is component mounting. Surface Mount Technology (SMT) is commonly used for this process. SMT involves placing the electronic components onto the PCB using automated pick-and-place machines. The components are then soldered onto the PCB using reflow soldering techniques, ensuring secure and reliable connections.

6. Assembly and Enclosure (200 words) Once the components are mounted, the LED driver undergoes assembly and enclosure. This involves integrating the PCB into a suitable housing or enclosure, providing protection against environmental factors and ensuring proper heat dissipation. The enclosure design must consider factors such as thermal management, electrical safety, and ease of installation.

7. Quality Control and Testing (250 words) Before the LED drivers are ready for market distribution, rigorous quality control and testing procedures are conducted. This includes functional testing, electrical performance testing, and safety compliance testing. Quality control measures ensure that each LED driver meets the required standards and specifications, minimizing the risk of product failures and ensuring customer satisfaction.

Conclusion (100 words) The mainstream LED driver production process involves several crucial steps, from component selection to final testing. Each step plays a vital role in ensuring the functionality, reliability, and safety of LED drivers. Manufacturers must carefully consider component selection, circuit design, prototyping, PCB manufacturing, component mounting, assembly, and quality control to produce high-quality LED drivers. Understanding this process provides valuable insights into the complexities involved in manufacturing LED lighting systems, contributing to the overall advancement and adoption of LED technology.